Taking care of your car’s timing belt is essential for maintaining your vehicle’s engine health and avoiding costly repairs. The timing belt, also known as a cambelt, is a critical component that synchronises the engine’s internal movements. Without proper maintenance, a failing timing belt can lead to catastrophic engine damage. This comprehensive guide will walk you through everything you need to know about timing belt maintenance.

Understanding your timing belt’s lifespan

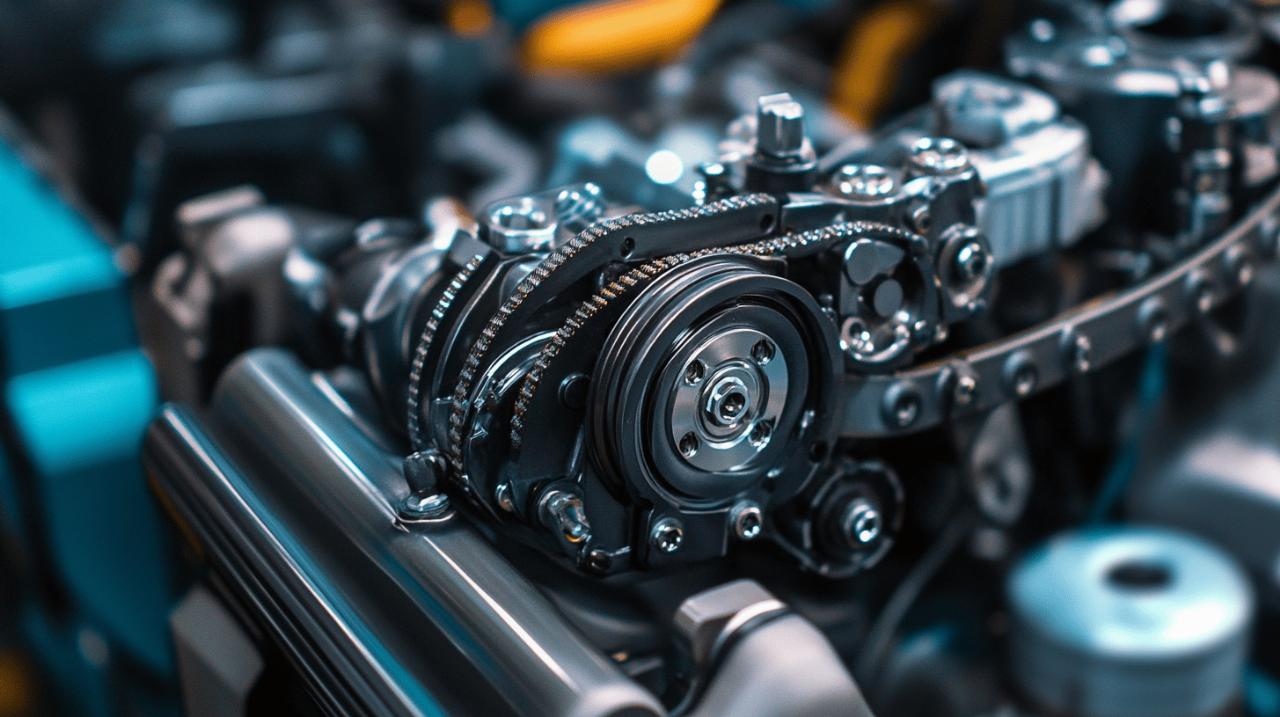

The timing belt is responsible for coordinating the rotation of the crankshaft and camshaft, ensuring that engine valves open and close at precisely the right moments during engine operation. According to Motor Publish, a leading automotive information resource, timing belts are typically made of reinforced rubber compounds designed to withstand high temperatures and constant use. Despite their durability, these belts inevitably wear down over time.

Reading your owner’s manual for replacement schedules

The most reliable source for determining when to replace your timing belt is your vehicle’s owner’s manual. Manufacturer recommendations generally suggest replacement intervals between 60,000 to 100,000 miles or every 5-10 years, depending on the make and model of your car. These guidelines are established based on extensive testing and should be followed diligently to avoid unexpected belt failure.

Typical timing belt durability factors

Several factors affect the longevity of your timing belt. The quality of materials used in manufacturing plays a significant role, with premium belts offering extended durability. Driving conditions also impact belt life—vehicles operating in extreme temperatures or dusty environments may require more frequent belt inspections. Even cars with low mileage need belt replacement due to age-related degradation of the rubber components, as the material naturally deteriorates over time regardless of use.

Recognising warning signs of timing belt wear

Being attentive to your engine’s performance can help you identify timing belt issues before they lead to complete failure. Early detection is crucial because once a timing belt snaps, the damage is often immediate and extensive.

Visual inspection techniques for belt damage

To inspect your timing belt, you’ll first need to locate it, which typically requires removing a plastic cover on the engine. Look for visible signs of wear such as fraying edges, cracks in the rubber, or glossy spots indicating excessive heat exposure. Also, check for missing teeth on the belt, as these are critical for maintaining proper engine timing. Belt tension is another important factor—a belt that’s too loose may slip, while one that’s too tight can cause premature wear on bearings and other components.

Unusual engine sounds that signal timing belt issues

Your car will often provide audible warnings when the timing belt begins to fail. Listen for distinctive ticking or squealing sounds coming from the engine, particularly during startup or acceleration. Engine misfires, rough idling, or difficulty starting are also common indicators of timing belt problems. If you notice oil leaks near the timing belt area, this could signal deterioration of related seals and gaskets, which might affect the belt’s performance.

Preventative replacement strategies

The smartest approach to timing belt maintenance is preventative rather than reactive. Planning for replacement before failure occurs can save you significant money and hassle.

Why proactive replacement saves money

When a timing belt breaks, it can cause the pistons to strike the valves in what’s known as an interference engine. This collision often results in bent valves, damaged pistons, and sometimes even a cracked cylinder head. The repair costs for such damage can easily exceed £2,000, compared to approximately £468 for a standard timing belt replacement. Beyond the financial aspect, proactive replacement also prevents the inconvenience and potential safety risks of unexpected breakdowns.

Creating a maintenance calendar for critical components

Developing a comprehensive maintenance schedule that includes timing belt replacement is essential for responsible car ownership. Many experts recommend documenting your vehicle’s service history in a dedicated logbook or digital application. Set reminders based on your manufacturer’s recommended intervals, adjusting as needed for your specific driving conditions. Consider aligning timing belt service with other major maintenance tasks to minimise garage visits and potentially reduce overall labour costs.

Associated components to consider

The timing belt doesn’t operate in isolation—it works in conjunction with several other important engine components that should be evaluated during belt replacement.

Water pump replacement timing

The water pump is often driven by the timing belt and typically has a similar lifespan. Since accessing the water pump requires much of the same disassembly as changing the timing belt, many mechanics recommend replacing both components simultaneously. This approach is particularly cost-effective because the labour charges for separate replacements would be substantially higher. Additionally, a failing water pump can leak coolant onto the timing belt, accelerating its deterioration.

Other parts to inspect during belt service

When replacing your timing belt, it’s wise to evaluate and potentially replace other components within the system. The tensioner, which maintains proper belt tightness, and various pulleys that guide the belt’s path can wear out over time. Belt guides and covers should also be inspected for damage. For comprehensive service, consider purchasing an all-inclusive timing belt kit that contains matched components designed to work together. Some modern engines, particularly those from manufacturers like Ford, Peugeot, and Citroen, utilise wet timing belts that operate within the engine’s oil system, requiring specialised maintenance procedures.

Professional vs diy timing belt maintenance

While some car owners might consider replacing a timing belt themselves, this is one maintenance task that often warrants professional attention.

When to trust a professional mechanic

Timing belt replacement requires precise alignment of timing marks on the crankshaft and camshaft, with zero margin for error. A slight misalignment can cause immediate engine damage upon startup. Professional mechanics have the experience, specialised tools, and technical information needed to ensure proper installation. Additionally, they can properly assess related components and provide a comprehensive service. For wet timing belts, which require access to internal engine components, professional service becomes even more critical due to the complexity involved.

Tools and skills needed for DIY enthusiasts

If you’re determined to replace your timing belt yourself, you’ll need a comprehensive set of tools including socket sets, specialised pullers, torque wrenches, and timing alignment tools specific to your vehicle model. Technical knowledge is essential—you must understand how to properly relieve tension from the system, align timing marks perfectly, and set proper belt tension. Access to service manuals or reliable online resources is crucial, as is the patience to follow each step methodically. Remember that mistakes can be costly, potentially resulting in significant engine damage that far outweighs any savings from DIY efforts.